The so-called vacuum cleaner micro switch can open the switch with a small force, the distance between the contacts is relatively small, and the torque is relatively large. Generally speaking, the size is divided into small and ultra-small, and one is ultra-small. Customers can see the size of the switch they need and buy it according to the specific situation. This is the function of the mouse buttons that we use a lot in our daily life, that is, the micro switch of the vacuum cleaner. So, what kind of environmental protection is required for the installation and use of this vacuum cleaner micro switch?

When manually welding the micro switch of the vacuum cleaner, try to make the temperature less than 320, and complete the configuration within 3 seconds. At the same time, be careful not to put pressure on the end department while working. Otherwise, the device may not work properly. If the switch is used at relatively small currents or voltages, it is recommended to choose a low power circuit, i.e. Au packet contacts. At the same time, pay attention to waterproofing when using the switch, and the temperature should also be within the specified range. Only when all of these conditions are met can these switches deliver the high power required to ensure proper operation of the device. Only in this way can the life of the switch be extended.

Precautions when using the micro switch of the vacuum cleaner:

● When fixing the switch body, use M2 small screws on the smooth surface with a torque of 0.098N m or less. Also, in order to prevent the screw from loosening again, it is recommended to use a washer at the same time.

● In the free state, the action body cannot directly exert force on the button or the rubber machine, and pay attention to the lateral force on the button when using it.

● Post-job job settings are based on 70[%] or more of the o.t. value. For switches, do not set the motion to the motion limit position. This does not reduce the life after opening and closing and movement associated with the impact.

● For manual soldering, please use electrical temperature 320 with temperature adjustment, complete the operation within 3 seconds, and be careful not to apply force to the terminal part during operation.

● It is recommended to use a low-power circuit type when using with a small current and voltage.

This article will show you the principle of the micro switch of the vacuum cleaner:

1. Small size, but convertible high current

Normally, closing a circuit creates a spark called arcing between the contacts. The higher the current, the easier it is to generate an arc, the slower the speed of switching the contacts, and the longer the duration of the arc, which becomes a factor for the deterioration of the contacts. The snap action mechanism of the micro switch can switch the contacts instantaneously, so the arc duration is short and the size is small, but it can be used in circuits with high current.

2. High precision.

The microswitch can basically switch pins at the same position even if it is repeatedly turned on/off, so the position detection error is small, and it is suitable for high-precision applications. This is also the advantage of a microswitch with a speed mechanism.

Micro switch characteristics

3. Durability

The arc duration is short and the contact damage is small, so the durability is improved.

4. Feel and sound

Snap-action instruments have a unique feel and sound during operation, and the operation can be confirmed by touch and hearing.

If you need a vacuum cleaner micro switch, you can contact us! We are IBAO, a professional manufacturer of micro switches in China!

We are contributing a better value!On the basis of comprehensive quality management,We continuously improve the quality and efficiency of team work.Strengthen the cooperation with customers and suppliers, and promote each other.Keep improving on the product quality and cost.Offer a better solution and support for customers.

★ Keep Improving

★ Superior Quality

★ Continuous Improvement

★ Pursuit of Excellence

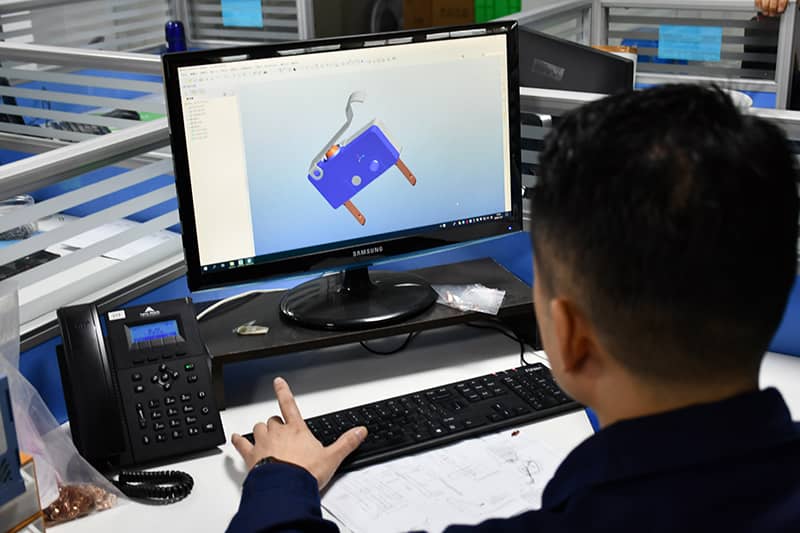

Product Research and Development

IBAO has a team of highly-educated and high professional competence staff.We can complete the development process independently covering research on customer demand,product concept formation, product design, mold design and development,automation equipment design and development and so on .We can also help customer solve the technical issues in production process and quality issues.

Injection Workshop

Total 35 injection machine(20T-150T)

Punching Workshop

Total 105 high-speed precision stamping machine

Post time: Aug-15-2022